Contact for Free Quotation & Sample, According to your needs, customize for you.

inquiry nowDirect Buried Fiber Optic Cable Construction Method

Direct buried fiber optic cable are designed to be installed directly into the ground without the need for additional protective conduits. This construction method offers several benefits, including cost savings and reduced installation time. Here’s an overview of the key aspects of the direct buried fiber optic cable construction method:

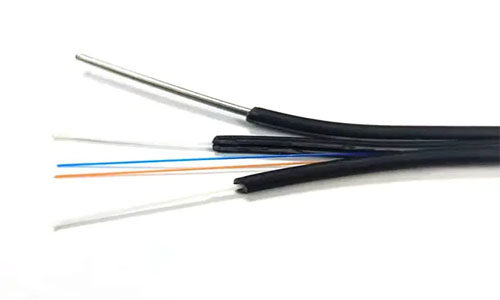

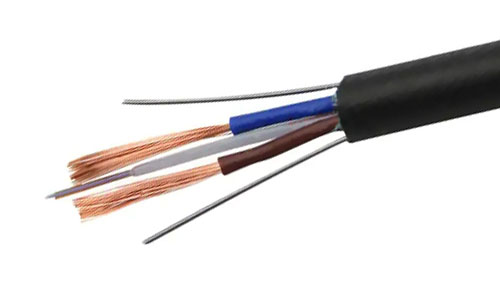

1. Cable Design and Structure

Outer Sheath: The outer sheath is typically made of a durable, high-density polyethylene (HDPE) or similar robust material. This provides protection against environmental factors such as moisture, chemicals, and mechanical damage.

Armor: Many direct buried cables include an armor layer, usually made of corrugated steel tape or other metallic materials, to protect against rodent damage and physical impacts.

Strength Members: These are embedded within the cable to provide additional tensile strength. Materials like aramid yarn (Kevlar) or fiberglass rods are commonly used.

Water Blocking Elements: To prevent water ingress, gel-filled or water-blocking tape is incorporated within the cable structure.

Buffer Tubes: The optical fibers are housed within buffer tubes that protect them from mechanical stress and environmental factors.

Optical Fibers: The core component, the optical fibers, are made from glass or plastic and are responsible for transmitting data via light signals.

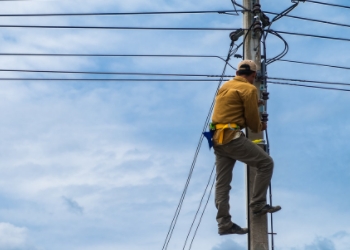

2. Installation Process

Trenching: A trench is excavated along the designated cable route. The depth and width of the trench depend on the specific requirements and local regulations, typically around 1-1.5 meters deep.

Bedding: A layer of soft, loose soil or sand is laid at the bottom of the trench to provide a cushion for the cable.

Laying the Cable: The fiber optic cable is unrolled and laid directly into the trench. Care is taken to avoid sharp bends and mechanical stresses that could damage the cable.

Backfilling: The trench is backfilled with excavated soil or sand, ensuring that the cable is properly covered and protected from direct impact.

Surface Restoration: The surface is restored to its original condition, which may involve replanting grass, repairing pavements, or other restorative measures.

3. Considerations and Best Practices

Route Planning: Thorough route planning is essential to avoid existing underground utilities and obstacles.

Environmental Protection: Measures should be taken to minimize environmental impact during installation.

Marker Tape: A detectable marker tape is often placed above the cable in the trench to alert future excavators to the presence of the cable.

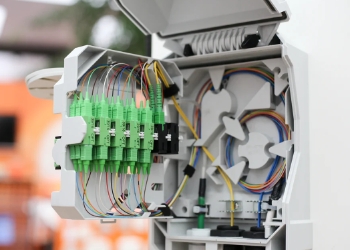

Testing and Documentation: After installation, the fiber optic cable is tested to ensure signal integrity. Detailed documentation of the installation process and cable route is also important.

4. Advantages

Cost-Effective: Eliminates the need for protective conduits, reducing material and labor costs.

Efficiency: Faster installation compared to other methods, such as placing cables in ducts.

Durability: Designed to withstand harsh environmental conditions and mechanical stresses.

5. Challenges

Initial Installation Disruption: Trenching can cause temporary disruption to the landscape and existing infrastructure.

Repair Complexity: In case of damage, accessing and repairing the cable can be more challenging compared to ducted installations.

Understanding the direct buried fiber optic cable construction method is crucial for telecom engineers, project managers, and installation teams to ensure reliable and efficient deployment of fiber optic networks. Proper planning, execution, and adherence to industry standards are key to a successful installation.

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs