Contact for Free Quotation & Sample, According to your needs, customize for you.

inquiry nowFiber Optic Fast Connector

Fiber Optic Fast Connector is a device used to quickly and easily terminate a fiber optic cable in the field. Unlike traditional fiber optic connectors, which require precise fiber cleaving, polishing, and epoxy curing processes, fast connectors allow for rapid installation with minimal tools and expertise. Here’s a more detailed overview:

Key Features

Pre-polished Ferrule: Fast connectors come with a pre-polished ferrule, which eliminates the need for polishing in the field.

Mechanical Splice: They use a mechanical splice mechanism to align and join the fiber ends within the connector, ensuring low insertion loss.

No Epoxy Required: Traditional connectors often require epoxy to hold the fiber in place. Fast connectors typically use a mechanical clamping system.

Field Installable: Designed for quick and easy installation in the field, often taking just a few minutes per connector.

Reusable: Some models can be reused if a termination is not done correctly on the first attempt.

Advantages

Time Efficiency: Significantly reduces the time required for termination, making them ideal for emergency repairs and quick installations.

Cost-Effective: Reduces the need for expensive equipment and consumables associated with traditional connectorization processes.

Ease of Use: Can be installed by technicians with minimal training, lowering the barrier to entry for fiber optic work.

Versatility: Suitable for a variety of environments, including telecom networks, data centers, and FTTH (Fiber to the Home) applications.

Installation Steps

Prepare the Fiber: Strip the fiber optic cable to expose the bare fiber. This usually involves removing the outer jacket, buffer, and coating.

Cleave the Fiber: Use a precision fiber cleaver to create a clean, flat end on the fiber.

Insert Fiber into Connector: Carefully insert the cleaved fiber into the fast connector until it reaches the pre-polished ferrule.

Secure the Fiber: Engage the mechanical clamping mechanism to hold the fiber in place.

Test the Connection: Use an optical power meter or a visual fault locator to verify the quality of the connection.

Applications

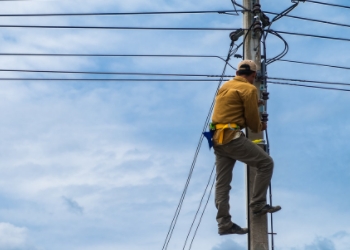

Telecommunications: Used in the deployment and maintenance of fiber optic networks for telecommunication services.

Data Centers: Useful for quick, reliable connections in data center environments.

FTTH Installations: Facilitates rapid connections in Fiber to the Home deployments.

Emergency Repairs: Ideal for scenarios where quick restoration of service is critical.

Common Types

SC (Subscriber Connector): Common in FTTH and LAN environments.

LC (Lucent Connector): Often used in data centers and high-density applications.

ST (Straight Tip): Typically used in legacy networks and multimode applications.

FC (Ferrule Connector): Common in telecom and long-haul networks.

Conclusion

Fiber Optic Fast Connectors are essential tools for modern fiber optic installations, providing a quick, reliable, and cost-effective solution for field terminations. Their ease of use and minimal tool requirements make them an indispensable asset for technicians and engineers working with fiber optic networks.

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable ASU Fiber Optic Cable

ASU Fiber Optic Cable OPGW Fiber Optic Cable

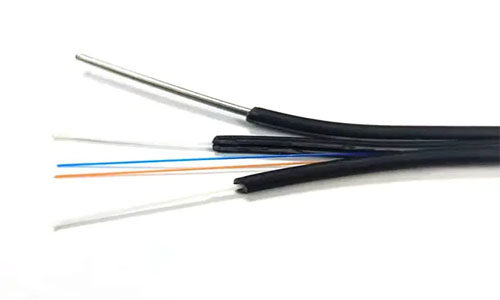

OPGW Fiber Optic Cable FTTH Fiber Optic Cable

FTTH Fiber Optic Cable Figure 8 Fiber Optic Cable

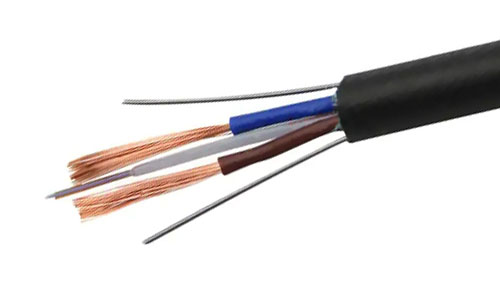

Figure 8 Fiber Optic Cable Photoelectric Composite Fiber Optic Cable

Photoelectric Composite Fiber Optic Cable Underground & Pipeline Fiber Optic Cable

Underground & Pipeline Fiber Optic Cable Air-Blown Micro Fiber Optic Cable

Air-Blown Micro Fiber Optic Cable Indoor Fiber Optic Cable

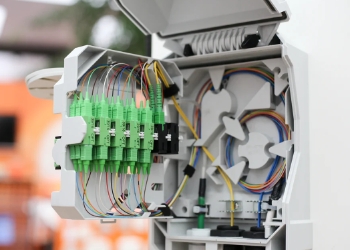

Indoor Fiber Optic Cable Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Splice Closure

Fiber Optic Splice Closure Fiber Optic Clamps

Fiber Optic Clamps Fiber Optic Cable Fittings

Fiber Optic Cable Fittings ADSS Fiber Cable

ADSS Fiber Cable ASU Fiber Cable

ASU Fiber Cable OPGW Fiber Cable

OPGW Fiber Cable FTTH Fiber Cable

FTTH Fiber Cable Figure 8 Fiber Cable

Figure 8 Fiber Cable Photoelectric Composite Fiber Cable

Photoelectric Composite Fiber Cable Underground & Pipeline Fiber Cable

Underground & Pipeline Fiber Cable Air-Blown Micro Fiber Cable

Air-Blown Micro Fiber Cable Aerial Fiber Cable

Aerial Fiber Cable Indoor Fiber Cable

Indoor Fiber Cable Fiber Optical Terminal Box

Fiber Optical Terminal Box Fiber Optic Distribution Box

Fiber Optic Distribution Box Multiport Service Termina Box

Multiport Service Termina Box Fiber Optic Clamps

Fiber Optic Clamps About Us

About Us Our Team

Our Team History

History R&D Strength

R&D Strength Production Base

Production Base Warehouse & Logistics

Warehouse & Logistics Quality

Quality FAQs

FAQs